Proper training is essential, covering scaffold hazards, drop protection, and assembly treatments. Routine examinations ensure safety and security and architectural honesty. Individual protective tools (PPE) safeguards employees from dangers with proper fitting and worldly choices. Safe and secure scaffolding by strongly anchoring and checking weather conditions. Adherence to fill limitations is crucial; distribute weight uniformly, recognize ability, and evaluate regularly. Executing these 5 suggestions is essential to a risk-free scaffolding procedure.

Correct training is necessary for ensuring the safety and efficiency of scaffolding operations. Training strategies play a crucial function in furnishing workers with the necessary skills to put up, take apart, and deal with scaffolding frameworks. These strategies may consist of hands-on demos, class direction, and substitute scenarios to prepare workers for real-world scenarios they might experience at work. In addition, qualification requirements ensure that workers have actually satisfied certain standards and possess the understanding and competence required to function securely on scaffolding.

To fulfill certification needs, employees may need to finish a formal training program that covers topics such as scaffold risks, fall defense, and correct assembly procedures. This training assists workers recognize the dangers related to scaffolding job and instructs them just how to alleviate these risks properly. By guaranteeing that employees are correctly trained and certified, companies can promote a society of safety and decrease the likelihood of crashes or injuries on scaffolding sites.

Carrying out regular inspections is vital for guaranteeing the continuous security and structural honesty of scaffolding systems. Inspections should be performed by qualified workers adhering to a recognized examination checklist. https://hillingdonscaffolding.co.uk This list ought to consist of things such as looking for any type of indicators of damages, making certain all connections are safe, validating the plumb and level of the scaffolding, and validating the proper installation of guardrails and toe boards.

In addition to normal evaluations, it is essential to have an organized upkeep schedule in position. This timetable should outline certain maintenance tasks, such as tightening bolts, changing used parts, and addressing any type of deterioration. By sticking to an upkeep timetable, possible concerns can be recognized and fixed immediately, decreasing the danger of crashes or architectural failings. https://hillingdonscaffolding.co.uk/index.html

Regular assessments and upkeep not only enhance security yet also extend the life-span of scaffolding systems. By proactively attending to any concerns, scaffolding can remain to offer a risk-free workplace for employees at heights.

To assure the safety of workers on scaffolding systems, the utilization of appropriate Personal Safety Devices (PPE) is vital. PPE plays a vital role in guarding employees from potential dangers that they might run into throughout scaffolding procedures. Making sure that PPE is correctly fitted is essential to optimize its protective abilities. Ill-fitting equipment can endanger safety and security by minimizing its efficiency in protecting workers from drops or various other threats. Therefore, workers must be trained to select PPE that fits them appropriately to keep the best security degrees.

Furthermore, the option of materials for PPE is equally important. Top notch materials can enhance longevity and comfort, urging workers to use their safety gear consistently. When picking PPE, aspects such as breathability, flexibility, and weight ought to be taken into consideration to ensure that the devices does not hinder workers' activities or trigger discomfort. By prioritizing appropriate fit and product choices in Individual Safety Equipment, companies can reduce the dangers connected with scaffolding procedures and promote a much safer work environment for their employees.

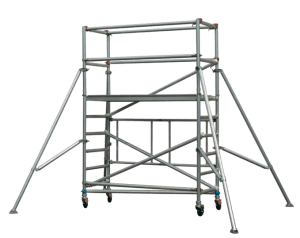

Maintaining the stability and stability of the scaffolding framework is important for the safety and security of employees and the success of building and construction projects. To secure the scaffolding effectively, anchor points need to be firmly established to the structure or framework. These support factors supply the necessary support to promote the security of the scaffolding. Regular checks and inspections of these anchor points must be carried out to ensure they remain in excellent condition and can birth the weight of the scaffold and employees.

In addition, climate condition play an essential function in the safety and security of the scaffolding. High winds, rainfall, or snow can jeopardize the stability of the structure, resulting in prospective crashes. It is important to keep an eye on weather forecasts and take essential preventative measures to safeguard the scaffolding throughout damaging climate condition.

Moreover, tie-offs should be made use of to better boost the security of the scaffolding. Workers should be appropriately connected off to the framework to stop drops and guarantee their security while operating at elevations. By sticking to these practices, the scaffolding can be firmly in place, decreasing the risk of accidents and injuries on the building and construction site.

Adherence to pack restrictions is crucial in ensuring the structural integrity and security of scaffolding procedures. Falling short to adhere to specified weight abilities can cause tragic crashes. To assure safe scaffolding techniques, take into consideration the following:

Tons Distribution: Disperse the weight evenly across the scaffolding structure. Concentrating weight on one area can lead to instability and prospective collapse.

Weight Capacity: Always understand the weight capability of the scaffolding system being utilized. Surpassing this limitation can compromise the whole structure.

Regular Examinations: Conduct regular inspections to check for any kind of indicators of straining or structural tension. Deal with any issues immediately.

Training and Interaction: Make certain all workers are educated on load restrictions and recognize the significance of adhering to them. Encourage open communication concerning any type of worries regarding weight distribution.

In the event of unanticipated extreme weather while working on scaffolding, focus on safety and security precautions by keeping an eye on weather updates, establishing clear interaction networks, and implementing emergency situation action and emptying procedures to assure the wellness of all workers entailed.

Regular examination has to be accomplished to ascertain the state of scaffolding products. Replacement timetable and security upgrades must line up with manufacturer referrals and sector standards. Maintenance requirements are vital to guarantee the safety and stability of scaffolding structures.

Safety precautions should be purely adhered to when working on scaffolding near high-voltage line or electrical resources to prevent electric threats. Rules usually mandate specific ranges that should be kept between scaffolding and high-voltage line for employee security.

To stop unauthorized access to scaffolding when not in use, rigorous gain access to control procedures need to be enforced. Implement protection procedures such as lockout/tagout treatments, physical obstacles, and routine inspections to prevent unauthorized access and assurance safety preventative measures are met.

Effective interaction is important for guaranteeing group security and sychronisation throughout scaffolding operations. Workers can make use of radios, hand signals, or marked communication indicate communicate information properly and promptly across various degrees, minimizing the danger of accidents.

In recap, adherence to ideal safety and security procedures is vital in scaffolding operations.

Training, inspections, PPE usage, safeguarding the scaffolding, and complying with lots restrictions are vital for avoiding crashes and making certain the wellness of employees.

By prioritizing safety measures, the risk of occurrences can be greatly reduced, developing a more secure workplace for all involved.